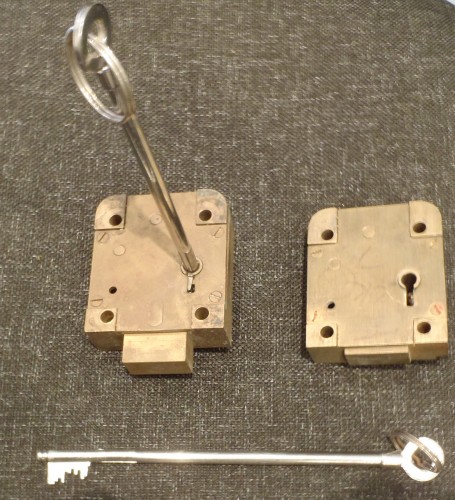

Tann 10 Lever Pin & Cam System

The Tann 10 lever lock was a mass produced high security lock fitted to Tann Safes & Vaults, Ratner Safes and British Ministry Safes over a period of about 50 years. the lock can come as either 3 or 7 gauge. It is a curtained lock with a good level of tolerance and reliability. The kit comes with two tools and one pin set meaning both locks can be opened with kit in under an hour.

The Pin & Cam System was developed by Falle-Safe Securities in 1991 and was initially designed for use on the Chubb Castle mortice lock. It is a highly effective and user friendly method of defeating most High Security Lever Locks and is effective regardless of

a) The quantity of levers contained in the mechanism.

b) Barrel and curtain or pick protector mechanisms.

c) False notching on levers designed to frustrate picking.

The term Pin & Cam refers to the original design, which used a small cam to apply lift to the pins in the key tip.

Method

The basic concept on which the system works is similar to that which is employed by the impressioning technique.

When impressioning a lever lock the user applies torque to the mechanism by way of a Blank key. This blank is then moved in relation to the mechanism which will in turn mark the surface of the key in any position where the levers are binding or not in the correct position.The user then files away the blank wherever the markings are and repeats the procedure until the key begins to form and the lock opens. The Pin & Cam System also carries out the same function but does it mechanically and in a more controlled and scientific way. Continued within the Tubular Key Tip is a specially designed Tester Mechanism.

The Tubular Key Tip has a series of holes along its length into which small pins can be placed. The length of these pins corresponds to the lengths of the normal cuts on a key effectively creating a Variable Key System. The Tester Mechanism is used during the decoding procedure to lift the pins and see if they are loose.

The user starts the process by inserting the longest pins into each of the holes on the tip effectively creating a blank key. The tool is then inserted into the lock and torque is applied to the levers by way of the Handle Grip. Each lever is then tested to see if it is loose and this is done by positioning the Tester Mechanism under each pin in turn. If the pin stiff and will not move freely it is because the lever is binding and in the incorrect position. This tells the user that the Pin in that position is the incorrect length and needs to be changed for a shorter none.

If the pin is loose it means that the lever is either in the correct position or not binding at that time and the Pin should therefore not be changed. Each time the user changes a Pin he is effectively changing the shape of the key and if the procedure is repeated the correct key shape will begin to form and the lock will eventually open.

False notching does not effect the system because all levers will eventually bind and only a lever, which is in the correct position, will remain loose until the lock opens.

Each Pin & Cam System is designed to be as user friendly as possible. The Pins are contained in a Pin Box and this is designed in such a way as to prevent the user from getting lost in the system. It only takes a few seconds to try each of the pins and discover the ones that need to be changed. Once the lock has opened the user will be able to determine the correct key code by reading off the codes of the Pins in the Key Tip.

System Advantages

This method is without doubt the most effective way of defeating high security lever lock mechanisms. The system is easy to use, relatively quick and provides the user with a working key and code for future use.

The Pin & Cam System was developed by Falle-Safe Securities in 1991 and was initially designed for use on the Chubb Castle mortice lock. It is a highly effective and user friendly method of defeating most High Security Lever Locks and is effective regardless of

a) The quantity of levers contained in the mechanism.

b) Barrel and curtain or pick protector mechanisms.

c) False notching on levers designed to frustrate picking.

The term Pin & Cam refers to the original design, which used a small cam to apply lift to the pins in the key tip.

Method

The basic concept on which the system works is similar to that which is employed by the impressioning technique.

When impressioning a lever lock the user applies torque to the mechanism by way of a Blank key. This blank is then moved in relation to the mechanism which will in turn mark the surface of the key in any position where the levers are binding or not in the correct position.The user then files away the blank wherever the markings are and repeats the procedure until the key begins to form and the lock opens. The Pin & Cam System also carries out the same function but does it mechanically and in a more controlled and scientific way. Continued within the Tubular Key Tip is a specially designed Tester Mechanism.

The Tubular Key Tip has a series of holes along its length into which small pins can be placed. The length of these pins corresponds to the lengths of the normal cuts on a key effectively creating a Variable Key System. The Tester Mechanism is used during the decoding procedure to lift the pins and see if they are loose.

The user starts the process by inserting the longest pins into each of the holes on the tip effectively creating a blank key. The tool is then inserted into the lock and torque is applied to the levers by way of the Handle Grip. Each lever is then tested to see if it is loose and this is done by positioning the Tester Mechanism under each pin in turn. If the pin stiff and will not move freely it is because the lever is binding and in the incorrect position. This tells the user that the Pin in that position is the incorrect length and needs to be changed for a shorter none.

If the pin is loose it means that the lever is either in the correct position or not binding at that time and the Pin should therefore not be changed. Each time the user changes a Pin he is effectively changing the shape of the key and if the procedure is repeated the correct key shape will begin to form and the lock will eventually open.

False notching does not effect the system because all levers will eventually bind and only a lever, which is in the correct position, will remain loose until the lock opens.

Each Pin & Cam System is designed to be as user friendly as possible. The Pins are contained in a Pin Box and this is designed in such a way as to prevent the user from getting lost in the system. It only takes a few seconds to try each of the pins and discover the ones that need to be changed. Once the lock has opened the user will be able to determine the correct key code by reading off the codes of the Pins in the Key Tip.

System Advantages

This method is without doubt the most effective way of defeating high security lever lock mechanisms. The system is easy to use, relatively quick and provides the user with a working key and code for future use.

Distributors for Falle-Safe Securities

Distributors for Falle-Safe Securities Member of the International Safe and Vault Technicians Association

Member of the International Safe and Vault Technicians Association